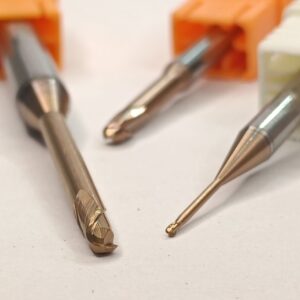

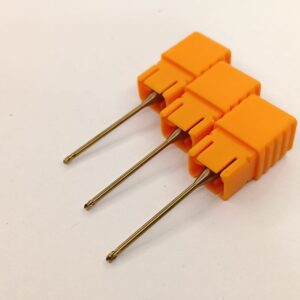

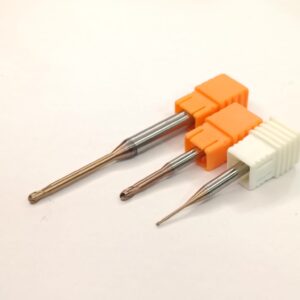

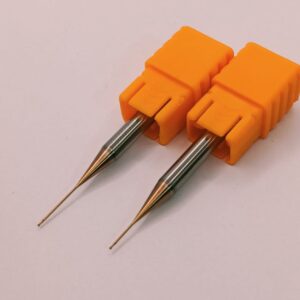

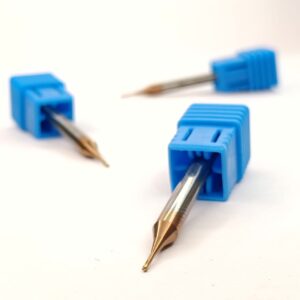

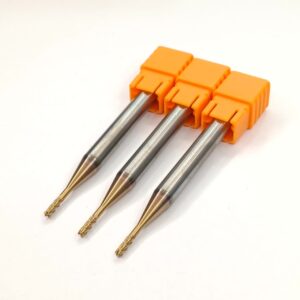

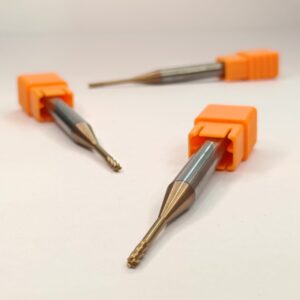

2HRB 55 R2.0xD6x25x50 2f Long Neck Ball Nose is a premium carbide end mill tool engineered for accurate deep-cavity finishing, rib milling, contour machining, and high-precision 3D surface profiling. Designed for mould makers and industrial CNC users, this cutter excels in machining 48–55 HRC materials such as P20, SS304, alloy steel, hardened steel, die steel, and tool steel used in injection moulds, forging dies, and precision tooling.

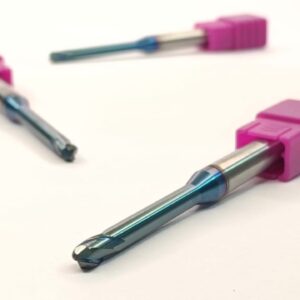

Its extended long-neck geometry provides secure access into deep pockets and narrow cavities without tool deflection. The optimized ball nose radius supports superior finishing on curved surfaces, tiny radii, sculpted profiles, and detailed core/cavity features. Manufactured using micro-grain carbide rod, the cutter offers high rigidity, excellent wear resistance, and consistent dimensional accuracy even during high-speed machining in modern VMCs and 5-axis CNC machines.

With 2-flute chip evacuation design, it ensures smooth cutting performance and reduced heat buildup while machining stainless and hardened steels. The advanced coating further enhances tool life, oxidation resistance, and heat stability, making it a perfect solution for high-load and long-cycle finishing applications. This cutter is widely preferred for die and mould machining tools, high performance end mills, carbide cutting tools for auto components, and precision carbide tools India.

Ideal for automotive die makers, aerospace component manufacturers, tool rooms, and CNC job shops seeking long-neck ball nose cutters for accurate finishing, high tool life, and mirror-grade surface output.