2HRB 55 R0.75xD4x12x50 2f

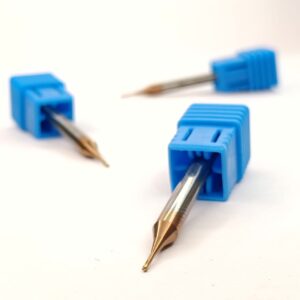

Original price was: ₹1,867.00.₹747.00Current price is: ₹747.00.High-precision 55 HRC long neck carbide ball nose end mill designed for deep cavity milling, 3D contouring, and hard material machining up to HRC 55.

Showing 1–144 of 271 results

High-precision 55 HRC long neck carbide ball nose end mill designed for deep cavity milling, 3D contouring, and hard material machining up to HRC 55.

High-precision 55 HRC long neck carbide ball nose end mill designed for deep cavity milling, 3D contouring, and hard material machining up to HRC 55.

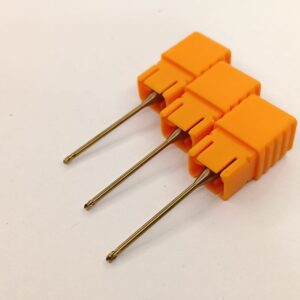

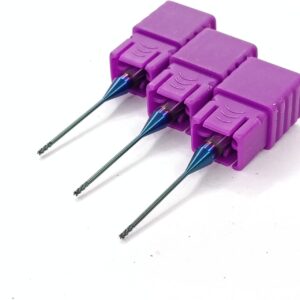

Carbide Long neck ball Nose 45 hrc- 2MRB R0.4xD4x4x50-2f (Rib)

Carbide long neck Ball Nose 45 hrc – 2MRB R0.4xD4x6x50-2f

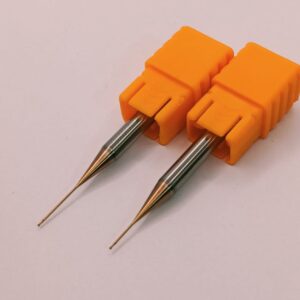

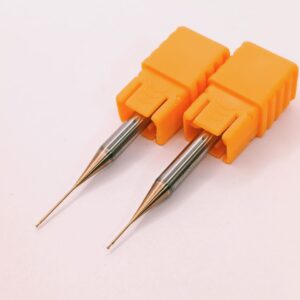

2MRE 0.3xD4x0.6(2)X50 2f 55 Mirco Rib end mill cutters for fine milling in hardened materials, ideal for miniature parts and precision components.

2MRE 0.8xD4x6x50 Long Neck ENd Mill cutters for fine milling in hardened materials, ideal for miniature parts and precision components.

327 16B25EC 08 – UFO T SLOT cutter body for indexable inserts, designed for high-performance T-slot milling in steel and alloy materials.

High-performance Cyclone T Slot milling inserts made from premium carbide for accurate, durable, and efficient T-slot machining on VMC machines.

High-performance Cyclone T Slot milling inserts made from premium carbide for accurate, durable, and efficient T-slot machining on VMC machines.

High-performance Cyclone T Slot milling inserts made from premium carbide for accurate, durable, and efficient T-slot machining on VMC machines.

327R06 1230002 GM1025-T slot Milling Cutter Inserts made from premium carbide for accurate, durable, and efficient T-slot machining on VMC machines.

327R06 12-2.5 GM1025-T slot Milling Cutter Inserts made from premium carbide for accurate, durable, and efficient T-slot machining on VMC machines.

327R08 16010 RM1025-T slot Milling Cutter Inserts made from premium carbide for accurate, durable, and efficient T-slot machining on VMC machines.

327R08 16 AG601025-T slot Milling Cutter Inserts made from premium carbide for accurate, durable, and efficient T-slot machining on VMC machines.

Uncoated, fine-polished carbide ball nose cutter for aluminium and soft alloys—ideal for high-speed VMC machining with excellent surface finish.

45ALB R1.0xD4x4x50 uncoated fine polished perfect for contouring and 3D profiling in mild steels and aluminum. Its highly polished surface enhances chip flow and resists buildup, ensuring cleaner cuts and improved tool life. Ideal for mold making, die work, and general machining, this ball nose cutter offers precision and reliability without coating. A cost-effective choice for smooth, burr-free surfaces in non-hardened materials.

45ALB R1.5xD4x6x50 uncoated fine polished perfect for contouring and 3D profiling in mild steels and aluminum. Its highly polished surface enhances chip flow and resists buildup, ensuring cleaner cuts and improved tool life. Ideal for mold making, die work, and general machining, this ball nose cutter offers precision and reliability without coating. A cost-effective choice for smooth, burr-free surfaces in non-hardened materials.

45ALB R2.0xD4x8x50 uncoated fine polished perfect for contouring and 3D profiling in mild steels and aluminum. Its highly polished surface enhances chip flow and resists buildup, ensuring cleaner cuts and improved tool life. Ideal for mold making, die work, and general machining, this ball nose cutter offers precision and reliability without coating. A cost-effective choice for smooth, burr-free surfaces in non-hardened materials.

45ALB R2.5xD5x10x50 uncoated fine polished perfect for contouring and 3D profiling in mild steels and aluminum. Its highly polished surface enhances chip flow and resists buildup, ensuring cleaner cuts and improved tool life. Ideal for mold making, die work, and general machining, this ball nose cutter offers precision and reliability without coating. A cost-effective choice for smooth, burr-free surfaces in non-hardened materials.

45ALB R3.0xD4x12x50 Uncoated Fine Polished perfect for contouring and 3D profiling in mild steels and aluminum. Its highly polished surface enhances chip flow and resists buildup, ensuring cleaner cuts and improved tool life. Ideal for mold making, die work, and general machining, this ball nose cutter offers precision and reliability without coating. A cost-effective choice for smooth, burr-free surfaces in non-hardened materials.

45ALB R3.0xD6x12x100 uncoated fine Polished perfect for contouring and 3D profiling in mild steels and aluminum. Its highly polished surface enhances chip flow and resists buildup, ensuring cleaner cuts and improved tool life. Ideal for mold making, die work, and general machining, this ball nose cutter offers precision and reliability without coating. A cost-effective choice for smooth, burr-free surfaces in non-hardened materials.

45ALB R3.0xD6x12x150 fine polished Ball nose cutter for aluminium and soft alloys—ideal for high-speed VMC machining with excellent surface finish.

Uncoated, fine-polished carbide ball nose cutter for aluminium and soft alloys—ideal for high-speed VMC machining with excellent surface finish.

Uncoated, fine-polished carbide ball nose cutter for aluminium and soft alloys—ideal for high-speed VMC machining with excellent surface finish.

Uncoated, fine-polished carbide ball nose cutter for aluminium and soft alloys—ideal for high-speed VMC machining with excellent surface finish.

Uncoated, fine-polished carbide ball nose cutter for aluminium and soft alloys—ideal for high-speed VMC machining with excellent surface finish.

Uncoated, fine-polished carbide ball nose cutter for aluminium and soft alloys—ideal for high-speed VMC machining with excellent surface finish.

Uncoated, fine-polished carbide ball nose cutter for aluminium and soft alloys—ideal for high-speed VMC machining with excellent surface finish.

45ALB R5.0xD10x20x75 fine polished Uncoated Ball Nose cutter perfect for contouring and 3D profiling in mild steels and aluminum. Its highly polished surface enhances chip flow and resists buildup, ensuring cleaner cuts and improved tool life. Ideal for mold making, die work, and general machining, this ball nose cutter offers precision and reliability without coating. A cost-effective choice for smooth, burr-free surfaces in non-hardened materials.

45ALB R6.0xD12x24x150 fine polished Uncoated Ball Nose are perfect for contouring and 3D profiling in mild steels and aluminum. Its highly polished surface enhances chip flow and resists buildup, ensuring cleaner cuts and improved tool life. Ideal for mold making, die work, and general machining, this ball nose cutter offers precision and reliability without coating. A cost-effective choice for smooth, burr-free surfaces in non-hardened materials.

45ALE 0.5x1xD4x50 3f Uncoated fine Polished carbide end mills is specially made for aluminium machining. It delivers a smooth finish, excellent chip flow, and long tool life. Buy from a trusted cutting tool dealer in Faridabad and top CNC tools supplier in India. Perfect for high-speed CNC operations on aluminium—available online with fast delivery.

45ALE 1.0x3xD4x50 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 1.5×4.5xD4x50 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

Precision uncoated fine polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

Precision uncoated fine polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 10.0xD10x55x150 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

Precision uncoated fine polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

Precision uncoated fine polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 12.0x45xD12x100 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 12.0xD12x55x150 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 14.0xD14x35x100 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 16.0x45xD16x100 Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 16.0xD16x45x100 2f Uncoated fine Polished end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 16.0xD16x50x150 3f Uncoated fine Polished end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 16.0xD16x80x150 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 18.0xD18x45x100 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 2.0x6xD4x50 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 2.0x6xD4x75 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 2.0xD4x8x100 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 2.0xD6x6x50 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 2.5×4.5xD4x75 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 2.5x8xD4x50 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 20.0xD20x45x100 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 3.0x12xD3x100 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

Precision uncoated fine polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 3.0x9xD3x50 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 3.0x9xD6x50 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 3.0xD4x9x50 Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 4.0x12xD4x50 3f Uncoated fine Polished end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 4.0x16xD4x75 3f Uncoated fine Polished end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 4.0x20xD4x100 3F Uncoated fine Polished end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 4.0xD6x12x50 3f Uncoated fine Polished-Precision uncoated fine polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 4.5xD6x15x50 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 5.0x18xD5x75 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 6.0xD6x18x50-3F Uncoated fine Polished Aluminium End Mill is designed for high-speed machining of aluminium and non-ferrous materials. Its mirror-polished flute ensures smooth chip removal and superior finish while minimizing built-up edge. The sharp cutting edge and friction-free design deliver clean, burr-free surfaces at high RPMs. Perfect for dry or mist-coolant cutting, this tool is ideal for finishing and semi-finishing applications in aerospace, die, mold, and precision part industries. With enhanced performance and reliability, it ensures longer tool life and better dimensional accuracy. Choose this end mill for a perfect blend of precision, speed, and surface quality in aluminium machining tasks.

45ALE 6.0xD6x25x75-3F Uncoated fine Polished Aluminium End Mill is designed for high-speed machining of aluminium and non-ferrous materials. Its mirror-polished flute ensures smooth chip removal and superior finish while minimizing built-up edge. The sharp cutting edge and friction-free design deliver clean, burr-free surfaces at high RPMs. Perfect for dry or mist-coolant cutting, this tool is ideal for finishing and semi-finishing applications in aerospace, die, mold, and precision part industries. With enhanced performance and reliability, it ensures longer tool life and better dimensional accuracy. Choose this end mill for a perfect blend of precision, speed, and surface quality in aluminium machining tasks.

45ALE 6.0xD6x30x100-3F Uncoated fine Polished-Fine Polished Uncoated Aluminium End Mill is designed for high-speed machining of aluminium and non-ferrous materials. Its mirror-polished flute ensures smooth chip removal and superior finish while minimizing built-up edge. The sharp cutting edge and friction-free design deliver clean, burr-free surfaces at high RPMs. Perfect for dry or mist-coolant cutting, this tool is ideal for finishing and semi-finishing applications in aerospace, die, mold, and precision part industries. With enhanced performance and reliability, it ensures longer tool life and better dimensional accuracy. Choose this end mill for a perfect blend of precision, speed, and surface quality in aluminium machining tasks.

45ALE 6.0xD6x40x150-3F Uncoated fine Polished for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 6.0xD6x45x150-3F Uncoated fine Polished Aluminium End Mill is designed for high-speed machining of aluminium and non-ferrous materials. Its mirror-polished flute ensures smooth chip removal and superior finish while minimizing built-up edge. The sharp cutting edge and friction-free design deliver clean, burr-free surfaces at high RPMs. Perfect for dry or mist-coolant cutting, this tool is ideal for finishing and semi-finishing applications in aerospace, die, mold, and precision part industries. With enhanced performance and reliability, it ensures longer tool life and better dimensional accuracy. Choose this end mill for a perfect blend of precision, speed, and surface quality in aluminium machining tasks.

45ALE 8.0x24xD8x60 3F Uncoated fine Polished end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 8.0x30xD8x75 3f Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 8.0x35xD8x100 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 8.0xD8x50x100 3F Uncoated fine Polished carbide end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

45ALE 8.0xD8x50X150 Uncoated fine Polished end mills for aluminum, copper, and soft metals. Ideal for high-speed, mirror finish machining.

High-speed machining made effortless with our DLC Coated Carbide End Mill for Aluminum. Designed for non-ferrous metals, this tool delivers low friction, excellent chip flow, and extended tool life. Perfect for achieving a mirror-like finish in aluminum, copper, and soft materials.

45ALE DLC 10.0xD10x40x100 3f Uncoated fine Polished with our DLC Coated Carbide End Mill for Aluminum. Designed for non-ferrous metals, this tool delivers low friction, excellent chip flow, and extended tool life. Perfect for achieving a mirror-like finish in aluminum, copper, and soft materials.

45ALE DLC 12.0xD12x35x75 Uncoated fine Polished with our DLC Coated Carbide End Mill for Aluminum. Designed for non-ferrous metals, this tool delivers low friction, excellent chip flow, and extended tool life. Perfect for achieving a mirror-like finish in aluminum, copper, and soft materials.

High-speed machining made effortless with our DLC Coated Carbide End Mill for Aluminum. Designed for non-ferrous metals, this tool delivers low friction, excellent chip flow, and extended tool life. Perfect for achieving a mirror-like finish in aluminum, copper, and soft materials.

High-speed machining made effortless with our DLC Coated Carbide End Mill for Aluminum. Designed for non-ferrous metals, this tool delivers low friction, excellent chip flow, and extended tool life. Perfect for achieving a mirror-like finish in aluminum, copper, and soft materials.

High-speed machining made effortless with our DLC Coated Carbide End Mill for Aluminum. Designed for non-ferrous metals, this tool delivers low friction, excellent chip flow, and extended tool life. Perfect for achieving a mirror-like finish in aluminum, copper, and soft materials.

High-speed machining made effortless with our DLC Coated Carbide End Mill for Aluminum. Designed for non-ferrous metals, this tool delivers low friction, excellent chip flow, and extended tool life. Perfect for achieving a mirror-like finish in aluminum, copper, and soft materials.

High-speed machining made effortless with our DLC Coated Carbide End Mill for Aluminum. Designed for non-ferrous metals, this tool delivers low friction, excellent chip flow, and extended tool life. Perfect for achieving a mirror-like finish in aluminum, copper, and soft materials.

The 45ALE-DLC Carbide End Mill is a high-performance cutting tool engineered for superior precision and durability in high-speed machining. Designed with DLC (Diamond-Like Carbon) coating, it delivers exceptional wear resistance, reduced friction, and extended tool life—ideal for machining aluminum, non-ferrous metals, plastics, and composites.

4HRE 55 1.5xD4x6x50 Long Neck End Mill perfect for precision milling in hard-to-reach areas. Designed for materials up to 38-45 HRC, including tool steel, and stainless steel, these cutters ensure high performance and long tool life.

Their long neck geometry allows deep cavity work without sacrificing rigidity. Ideal for mould making, aerospace, and automotive sectors, these end mills offer superior surface finish and vibration-free cutting. Made from high-grade carbide and advanced coatings, they ensure excellent wear resistance and smooth chip removal. Choose from a wide range of sizes for your CNC milling needs.

Shop premium 65 HRC long neck carbide end mills for deep cavity and hard steel machining. Durable, precise, and ideal for tool & die industry.

Precision chamfering made easy with our solid carbide chamfer tool – perfect for deburring, edge breaking, and countersinking in steel, aluminum, and more. High accuracy, long tool life, and clean surface finish for every job.

Precision chamfering made easy with our solid carbide chamfer tool – perfect for deburring, edge breaking, and countersinking in steel, aluminum, and more. High accuracy, long tool life, and clean surface finish for every job.

High-performance APMT 1135 H2 carbide milling insert with H2 chipbreaker for smooth cutting, efficient chip control, and long tool life. Ideal for CNC face milling, pocketing, and shoulder operations on steel, cast iron, and non-ferrous metals.

APMT 1604 H2 GM7030 optimized for CNC milling and superior chip control. Featuring the H2 chip breaker and high-performance GM7030 grade, this indexable insert delivers excellent wear resistance and thermal stability for steel and die steel machining. Perfect for precision applications in mold, aerospace, and automotive industries. The APMT1604 H2 insert ensures long tool life, smooth surface finish, and fast, hassle-free insert changes for efficient production.

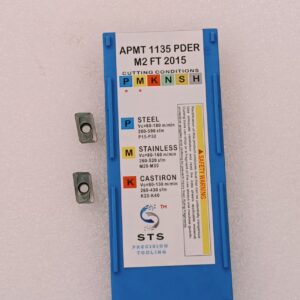

APMT1135 PDER M2 FM2085 indexable insert, a PVD-coated carbide cutter delivering precision and wear resistance for steel, stainless steel, and cast iron. This APMT 1135 carbide insert offers excellent chip control, thermal stability, and surface finish. Perfect for CNC milling, face and shoulder operations, and compatible with standard tool holders. Enhance cutting accuracy and tool life with this reliable, high-performance APMT PDER insert used in mold, automotive, and aerospace machining sectors.

APMT1135PDER M2 FT2015 Milling Insert APMT1135 PDER M2 FT2015 carbide insert is designed for precision CNC milling with superior wear resistance and long tool life. Ideal for face, shoulder, and pocket milling, it offers excellent performance on alloy steel, stainless steel, and cast iron. Its optimized chip breaker ensures smooth cutting and efficient heat management, reducing downtime. Backed by Sukhmani Total Solutions, this insert guarantees consistent accuracy and productivity for demanding automotive, aerospace, mold, and general engineering applications.

APMT1604PDER M2 FM2085 carbide insert delivering precision and wear resistance for steel, stainless steel, and cast iron. This APMT 1604 carbide insert offers excellent chip control, thermal stability, and surface finish. Perfect for CNC milling, face and shoulder operations, and compatible with standard tool holders. Enhance cutting accuracy and tool life with this reliable, high-performance APMT PDER insert used in mold, automotive, and aerospace machining sectors.

ASM07R 08 C08 100-High Feed Milling Cutter compatible with JDMT07 inserts built for high-efficiency roughing in hard-to-machine materials. Designed with aggressive rake geometry and optimized insert placement, it reduces cutting resistance and increases feed rates, making it ideal for die & mold, aerospace, and general engineering industries. Its sturdy construction ensures vibration-free performance, while wear-resistant inserts offer long-lasting durability. Whether slotting, pocketing, or facing, the ASM cutter ensures fast, reliable results with lower cycle times. Perfect for CNC operations demanding speed, accuracy, and cost-efficiency.

Precision 90° back chamfer cutter for reverse deburring and internal chamfering—ideal for CNC machining of steel, aluminum, and alloys.

Precision 90° back chamfer cutter for reverse deburring and internal chamfering—ideal for CNC machining of steel, aluminum, and alloys.

Precision 90° back chamfer cutter for reverse deburring and internal chamfering—ideal for CNC machining of steel, aluminum, and alloys.

Precision 90° back chamfer cutter for reverse deburring and internal chamfering—ideal for CNC machining of steel, aluminum, and alloys.

Precision 90° back chamfer cutter for reverse deburring and internal chamfering—ideal for CNC machining of steel, aluminum, and alloys.

Precision 90° back chamfer cutter for reverse deburring and internal chamfering—ideal for CNC machining of steel, aluminum, and alloys.

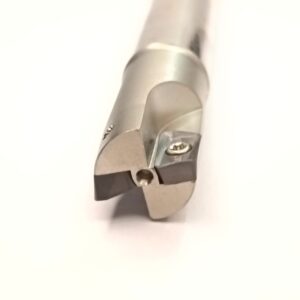

BAP300R 10-C10-130 alloy steel indexable cutter body is engineered for high-performance milling with APMT1135 inserts. Built for precision, rigidity, and durability, it delivers excellent results in roughing and semi-finishing operations across steel, stainless steel, and cast iron. Ideal for CNC and VMC applications, it offers smooth cutting, extended tool life, and easy insert replacement. Perfect for industries like automotive, die & mold, and general engineering, the BAP300R ensures consistent, vibration-free machining even in demanding environments.

BAP300R 12-C12-130 alloy steel indexable cutter body is engineered for high-performance milling with APMT1135 inserts. Built for precision, rigidity, and durability, it delivers excellent results in roughing and semi-finishing operations across steel, stainless steel, and cast iron. Ideal for CNC and VMC applications, it offers smooth cutting, extended tool life, and easy insert replacement. Perfect for industries like automotive, die & mold, and general engineering, the BAP300R ensures consistent, vibration-free machining even in demanding environments.

BAP300R 16-C16-150 alloy steel indexable cutter body is engineered for high-performance milling with APMT1135 inserts. Built for precision, rigidity, and durability, it delivers excellent results in roughing and semi-finishing operations across steel, stainless steel, and cast iron. Ideal for CNC and VMC applications, it offers smooth cutting, extended tool life, and easy insert replacement. Perfect for industries like automotive, die & mold, and general engineering, the BAP300R ensures consistent, vibration-free machining even in demanding environments.

BAP300R 16-C16-200 alloy steel cutter body made from premium alloy steel. Designed for precision and durability, this tool holder is perfectly compatible with APMT1135 inserts, delivering exceptional surface finish and chip control during high-speed machining. Ideal for roughing and semi-finishing in steel, stainless steel, and cast iron, the BAP300R cutter body ensures excellent rigidity, long tool life, and reduced vibration. Its sturdy build supports efficient cutting under demanding conditions, while easy insert replacement minimizes downtime. Widely used in CNC and VMC machines, this cutter body is a reliable solution for industrial machining needs. Upgrade your productivity and machining quality with the BAP300R – engineered to perform and built to last. Suitable for automotive, aerospace, die & mold, and general engineering sectors. Trust in consistent performance with every cut.

BAP300R 16-M8-2T MODULAR CUTTER is engineered for precise and efficient metal cutting using APMT inserts. Made from high-strength alloy steel, it offers exceptional rigidity, durability, and smooth chip evacuation. Ideal for CNC and VMC operations in steel, stainless steel, and cast iron machining. Its modular design ensures versatility, faster insert changes, and reliable performance in demanding applications. Perfect for automotive, die & mold, and general engineering industries seeking consistent, high-speed machining.

BAP300R 20-M10-2T MODULAR CUTTER is engineered for precise and efficient metal cutting using APMT inserts. Made from high-strength alloy steel, it offers exceptional rigidity, durability, and smooth chip evacuation. Ideal for CNC and VMC operations in steel, stainless steel, and cast iron machining. Its modular design ensures versatility, faster insert changes, and reliable performance in demanding applications. Perfect for automotive, die & mold, and general engineering industries seeking consistent, high-speed machining.

BAP400R 25-C25-150 Precision Indexable End mill, compatible with APMT 1604 inserts, designed for efficient CNC face milling in steel and alloy materials. The BAP400R Indexable End Mill offers high-precision face and shoulder milling with easy insert replacement. Designed for APMT inserts, it delivers excellent surface finish and chip control. Ideal for steel, cast iron, and non-ferrous metals. Choose Sukhmani Total Solutions for performance-driven indexable milling tools built to boost CNC productivity and reduce tooling costs.

BT40 Clamping Fixture Aluminium Body – Precision Industrial Tool Holder Locking for safe and stable handling of milling adaptors during tool assembly and maintenance.

BT40 DC12 100 G2.5 0.003 DMC Adaptor Enhance your milling operations with the BT40 – DMC adaptor 0.003 accuracy, designed for superior runout control and secure tool holding in CNC machining. Engineered from high-quality materials, it delivers excellent precision and supports tight tolerances for demanding milling tasks. Ideal for mold making, aerospace, and fine-feature machining, this adaptor ensures reliable clamping, minimal vibration, and longer tool life. Compatible with precise collets, the BT40 – DMC adaptor maximizes productivity and quality for professionals requiring exceptional machining accuracy.

BT40 DC12 150 DMC Adaptor (0.003 G2.5) designed for superior runout control and secure tool holding in CNC machining. Engineered from high-quality materials, it delivers excellent precision and supports tight tolerances for demanding milling tasks. Ideal for mold making, aerospace, and fine-feature machining, this adaptor ensures reliable clamping, minimal vibration, and longer tool life. Compatible with precise collets, the BT40 – DMC adaptor maximizes productivity and quality for professionals requiring exceptional machining accuracy.

BT40 DC6 100 (G2.5 0.003) DMC Adaptor for die & mould applications—ideal for high-speed CNC machining with excellent tool stability and finish.

BT40 DC6 120 DMC Adaptor (G2.5 0.003) Balanced delivers exceptional precision for CNC machining, ensuring minimal runout and high spindle stability. Designed for high-speed milling and drilling, this BT40 collet chuck guarantees superior clamping force, vibration reduction, and extended tool life. Perfect for HSK & BT tool holders, it meets G2.5 25,000 RPM balance standards. Ideal for aerospace, mold, and automotive industries, this balanced BT40 DMC chuck boosts machining accuracy and surface finish in demanding applications.

BT40 DC6 150 (G2.5 0.003) Die and Mould Chuck designed for superior runout control and secure tool holding in CNC machining. Engineered from high-quality materials, it delivers excellent precision and supports tight tolerances for demanding milling tasks. Ideal for mold making, aerospace, and fine-feature machining, this adaptor ensures reliable clamping, minimal vibration, and longer tool life. Compatible with precise collets, the BT40 – DMC adaptor maximizes productivity and quality for professionals requiring exceptional machining accuracy.

BT40 DC6 200 Die and Mould Chuck (G2.5 0.003) – designed for superior runout control and secure tool holding in CNC machining. Engineered from high-quality materials, it delivers excellent precision and supports tight tolerances for demanding milling tasks. Ideal for mold making, aerospace, and fine-feature machining, this adaptor ensures reliable clamping, minimal vibration, and longer tool life. Compatible with precise collets, the BT40 – DMC adaptor maximizes productivity and quality for professionals requiring exceptional machining accuracy.

C-power collet C25-12 collet for stable tool holding in CNC milling, drilling, and tapping operations with superior clamping and accuracy.

C-power collet C25-14 offers exceptional precision, 0.003mm runout, and strong gripping power for CNC machining. Perfect for milling, drilling, and turning, it delivers stability, reduced vibration, and longer tool life. Compatible with various CNC chucks and tool holders, it ensures superior accuracy in machining hardened steel, stainless steel, and alloys. Ideal for aerospace, automotive, and die-mould industries, this C-POWER C25 collet guarantees reliable, high-speed performance in demanding production environments.

C-power collet C25-16 offers exceptional precision, 0.003mm runout, and strong gripping power for CNC machining. Perfect for milling, drilling, and turning, it delivers stability, reduced vibration, and longer tool life. Compatible with various CNC chucks and tool holders, it ensures superior accuracy in machining hardened steel, stainless steel, and alloys. Ideal for aerospace, automotive, and die-mould industries, this C-POWER C25 collet guarantees reliable, high-speed performance in demanding production environments.

C-power collet C25-6 offers exceptional precision, 0.003mm runout, and strong gripping power for CNC machining. Perfect for milling, drilling, and turning, it delivers stability, reduced vibration, and longer tool life. Compatible with various CNC chucks and tool holders, it ensures superior accuracy in machining hardened steel, stainless steel, and alloys. Ideal for aerospace, automotive, and die-mould industries, this C-POWER C25 collet guarantees reliable, high-speed performance in demanding production environments.

C-power collet C32-10 offers exceptional precision, 0.003mm runout, and strong gripping power for CNC machining. Perfect for milling, drilling, and turning, it delivers stability, reduced vibration, and longer tool life. Compatible with various CNC chucks and tool holders, it ensures superior accuracy in machining hardened steel, stainless steel, and alloys. Ideal for aerospace, automotive, and die-mould industries, this C-POWER C32 collet guarantees reliable, high-speed performance in demanding production environments.

C-Power collet C32-16 by Sukhmani Toolings offer superior grip, excellent run-out control, and long tool life for CNC turning, Swiss machines, and tool holders. Engineered for durability and accuracy, they ensure reliable clamping in high-speed and high-load operations. Ideal for automotive, aerospace, and general machining applications, these collets deliver consistent performance and minimal vibration. Choose C Power Collets for improved productivity and precision holding in all demanding machining environments.

C-Power Collet C32-25 by Sukhmani Toolings offer superior grip, excellent run-out control, and long tool life for CNC turning, Swiss machines, and tool holders. Engineered for durability and accuracy, they ensure reliable clamping in high-speed and high-load operations. Ideal for automotive, aerospace, and general machining applications, these collets deliver consistent performance and minimal vibration. Choose C Power Collets for improved productivity and precision holding in all demanding machining environments.

C-Power Collet C32-3 by Sukhmani Toolings offer superior grip, excellent run-out control, and long tool life for CNC turning, Swiss machines, and tool holders. Engineered for durability and accuracy, they ensure reliable clamping in high-speed and high-load operations. Ideal for automotive, aerospace, and general machining applications, these collets deliver consistent performance and minimal vibration. Choose C Power Collets for improved productivity and precision holding in all demanding machining environments.

C-Power collet C32-4 by Sukhmani Toolings offer superior grip, excellent run-out control, and long tool life for CNC turning, Swiss machines, and tool holders. Engineered for durability and accuracy, they ensure reliable clamping in high-speed and high-load operations. Ideal for automotive, aerospace, and general machining applications, these collets deliver consistent performance and minimal vibration. Choose C Power Collets for improved productivity and precision holding in all demanding machining environments.

C-Power Collet C32-6 by Sukhmani Toolings offer superior grip, excellent run-out control, and long tool life for CNC turning, Swiss machines, and tool holders. Engineered for durability and accuracy, they ensure reliable clamping in high-speed and high-load operations. Ideal for automotive, aerospace, and general machining applications, these collets deliver consistent performance and minimal vibration. Choose C Power Collets for improved productivity and precision holding in all demanding machining environments.

C-Power collet C32-8 for stable tool holding in CNC milling, drilling, and tapping operations with superior clamping and accuracy.

C04 SCLCL 0305 Carbide Boring Bar bar is a compact, precision tool ideal for internal turning and boring in tight spaces. Built from high-quality carbide, it offers excellent rigidity, vibration resistance, and wear life. Compatible with CCMT 0305 inserts, this tool is perfect for fine-tolerance machining in CNC lathes, especially in aerospace and die & mold industries. Its efficient chip evacuation and stable performance ensure smooth, accurate results in small-diameter bores and difficult-to-machine materials.

C04 SCLCR 0305 carbide boring bar is a compact, precision tool ideal for internal turning and boring in tight spaces. Built from high-quality carbide, it offers excellent rigidity, vibration resistance, and wear life. Compatible with CCMT 0305 inserts, this tool is perfect for fine-tolerance machining in CNC lathes, especially in aerospace and die & mold industries. Its efficient chip evacuation and stable performance ensure smooth, accurate results in small-diameter bores and difficult-to-machine materials.

Precision C05 SCLCL/R 04-06 carbide boring bar, suitable for CCGT 04 inserts, ideal for fine internal turning in CNC and Swiss-type machining applications.

C05 SCLCR 0406 Carbide Boring Bar is a precision tool for internal boring and turning. Made from solid carbide, it offers excellent rigidity, vibration resistance, and high accuracy. Designed to fit CCMT/CCGT inserts, it is ideal for machining steel, stainless steel, brass, and non-ferrous metals. Perfect for miniature parts, molds, aerospace, and medical applications, it ensures smooth cutting, long tool life, and reliable performance. Backed by Sukhmani Total Solutions, it is the ultimate choice for precision boring.

C06H SCLCL 06 Carbide Boring Bar is a precision tool for internal boring and turning. Made from solid carbide, it offers excellent rigidity, vibration resistance, and high accuracy. Designed to fit CCMT/CCGT inserts, it is ideal for machining steel, stainless steel, brass, and non-ferrous metals. Perfect for miniature parts, molds, aerospace, and medical applications, it ensures smooth cutting, long tool life, and reliable performance. Backed by Sukhmani Total Solutions, it is the ultimate choice for precision boring.

C06H SCLCR 06 Carbide Boring Bar is a high-precision miniature tool engineered for accurate boring, internal turning, and profiling applications. Made from premium solid carbide, it ensures maximum rigidity, vibration resistance, and superior surface finish, even in deep boring operations.

This boring bar is specifically designed to hold CCMT/CCGT inserts, providing excellent clamping stability and smooth cutting action. With its compact size and strong carbide shank, the C05 SCLCR 0406 is ideal for high-precision machining of steel, stainless steel, alloy steel, brass, copper, and non-ferrous metals.

The tool’s micro-diameter configuration makes it especially useful in miniature components, mold making, watch parts, aerospace, medical equipment, and precision engineering where accuracy is critical. Its optimized geometry reduces tool deflection, improves dimensional accuracy, and enhances tool life.

Backed by Sukhmani Total Solutions, the C05 SCLCR 0406 Carbide Boring Bar offers consistent performance, durability, and efficiency in CNC machining. A trusted solution for manufacturers seeking precision boring in small-diameter applications, this tool guarantees reliable performance and cost-effectiveness.

C08 SCLCL 06 (Carbide B.Bar) is a precision tool for internal boring and turning. Made from solid carbide, it offers excellent rigidity, vibration resistance, and high accuracy. Designed to fit CCMT/CCGT inserts, it is ideal for machining steel, stainless steel, brass, and non-ferrous metals. Perfect for miniature parts, molds, aerospace, and medical applications, it ensures smooth cutting, long tool life, and reliable performance. Backed by Sukhmani Total Solutions, it is the ultimate choice for precision boring.

C10K SCLCL 06 CARBIDE BORING BAR is a precision tool for internal boring and turning. Made from solid carbide, it offers excellent rigidity, vibration resistance, and high accuracy. Designed to fit CCMT/CCGT inserts, it is ideal for machining steel, stainless steel, brass, and non-ferrous metals. Perfect for miniature parts, molds, aerospace, and medical applications, it ensures smooth cutting, long tool life, and reliable performance. Backed by Sukhmani Total Solutions, it is the ultimate choice for precision boring.

High-strength carbide boring bar compatible with CCMT 06 inserts, ideal for internal turning, profiling, and boring in steel, stainless steel, and cast iron.

Carbide Micro Ball Nose 45 hrc – 2MRB R0.15xD4x0.6×50-2f –

Carbide mirco Drill 1.0xD3x10.5×50

Carbide Shank 10 M6 100L for modular cutters delivers precision, rigidity, and stability for CNC machining. Made from premium carbide, it minimizes vibration, enhances accuracy, and extends tool life in heavy milling operations. Ideal for indexable modular cutters, it ensures consistent results in aerospace, automotive, die-mould, and general machining. Sukhmani Total Solutions provides high-precision carbide shanks designed for superior performance, excellent wear resistance, and long-term reliability, making them the best choice for demanding CNC milling applications.

Carbide T Slot 6xH1x50 4T – T-Slot Milling Cutter are designed for precision slotting operations, offering excellent wear resistance and durability. Ideal for creating T-slots in various materials with high accuracy and clean finishes.

Durable 45 HRC carbide ball nose cutters for precision 3D machining and contouring in mild steel, alloy steel, and general-purpose materials.

CEM 2.0x6xD4x75 Flat End Mill for excellent wear resistance, precision, and tool longevity. Ideal for milling mild steel, alloy steel, and pre-hardened materials, these end mills ensure smooth, vibration-free cutting. The bronze coating reduces friction and enhances surface finish, making them perfect for consistent CNC operations. Choose Sukhmani Total Solutions for premium-quality carbide tools that offer reliability, long tool life, and precision at every step of your machining process.

CEM 2.5×7.5xD4x50 Flat End Mill for excellent wear resistance, precision, and tool longevity. Ideal for milling mild steel, alloy steel, and pre-hardened materials, these end mills ensure smooth, vibration-free cutting. The bronze coating reduces friction and enhances surface finish, making them perfect for consistent CNC operations. Choose Sukhmani Total Solutions for premium-quality carbide tools that offer reliability, long tool life, and precision at every step of your machining process.

CEM 2.5×7.5xD4x75 Flat End Mill built for excellent wear resistance, precision, and tool longevity. Ideal for milling mild steel, alloy steel, and pre-hardened materials, these end mills ensure smooth, vibration-free cutting. The bronze coating reduces friction and enhances surface finish, making them perfect for consistent CNC operations. Choose Sukhmani Total Solutions for premium-quality carbide tools that offer reliability, long tool life, and precision at every step of your machining process.

CEM 20.0xD20x45x100 Flat End Mill built for excellent wear resistance, precision, and tool longevity. Ideal for milling mild steel, alloy steel, and pre-hardened materials, these end mills ensure smooth, vibration-free cutting. The bronze coating reduces friction and enhances surface finish, making them perfect for consistent CNC operations. Choose Sukhmani Total Solutions for premium-quality carbide tools that offer reliability, long tool life, and precision at every step of your machining process.

CEM 3.0x12xD3x100 Flat End Mill built for excellent wear resistance, precision, and tool longevity. Ideal for milling mild steel, alloy steel, and pre-hardened materials, these end mills ensure smooth, vibration-free cutting. The bronze coating reduces friction and enhances surface finish, making them perfect for consistent CNC operations. Choose Sukhmani Total Solutions for premium-quality carbide tools that offer reliability, long tool life, and precision at every step of your machining process.

CEM 3.0x12xD3x75 Flat End Mill for excellent wear resistance, precision, and tool longevity. Ideal for milling mild steel, alloy steel, and pre-hardened materials, these end mills ensure smooth, vibration-free cutting. The bronze coating reduces friction and enhances surface finish, making them perfect for consistent CNC operations. Choose Sukhmani Total Solutions for premium-quality carbide tools that offer reliability, long tool life, and precision at every step of your machining process.

4HRE 65 1.5xD4x20x50 4f Rib

1 × ₹1,087.00

4HRE 65 1.5xD4x20x50 4f Rib

1 × ₹1,087.00  2MRB R0.4xD4x4x50 2f (Rib)

1 × ₹468.00

2MRB R0.4xD4x4x50 2f (Rib)

1 × ₹468.00 Subtotal: ₹1,555.00

WhatsApp us