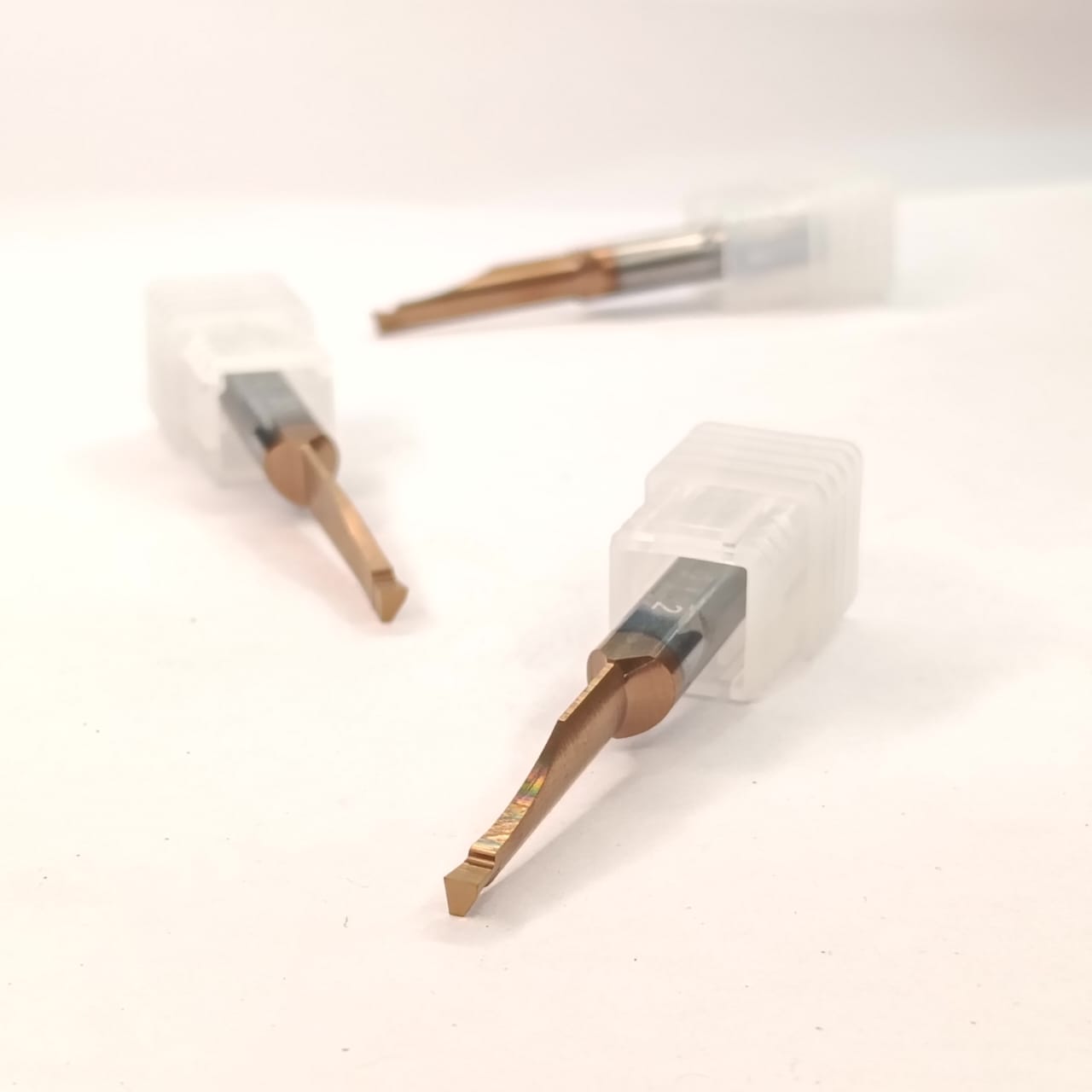

MVR 06 B2.0 L 22 Deep Face Grooving Picco Tool

Original price was: ₹4,498.00.₹2,474.00Current price is: ₹2,474.00.

MVR 06 B2.0 L 22 deep face grooving Picco tool is a high-precision carbide grooving tool for CNC lathes. With a 2.0 mm cutting width and 22 mm reach, it is ideal for deep, narrow face grooves, O-ring slots, and sealing grooves. Designed for stainless steel, alloy steel, and hardened materials, it delivers smooth cutting, low vibration, and long tool life for precision turning and production machining.

Out of stock

We Ship All Over India

- Secure Payment Mode: Bank Transfer Only

- Returns & Refunds Available Within 7 Days

Description

MVR 06 B2.0 L 22 Deep Face Grooving Picco Tool is a high-precision miniature carbide grooving tool designed for deep face grooving, narrow slot machining, and micro-turning operations on modern CNC lathes and Swiss-type machines. With a 2.0 mm cutting width and 22 mm effective cutting length, this tool is ideal for producing clean, accurate, and deep grooves in compact components where standard grooving tools cannot reach.

Manufactured from premium micro-grain solid carbide with a wear-resistant coating, this Picco tool offers excellent edge stability, heat resistance, and long tool life when machining stainless steel, alloy steel, tool steel, hardened steel, and non-ferrous metals. The optimized Picco geometry ensures low cutting force, smooth chip flow, and vibration-free machining, making it perfect for high-speed CNC turning and precision grooving applications.

The MVR 06 B2.0 L 22 is widely used for machining O-ring grooves, sealing grooves, oil grooves, and face slots in industries such as automotive, aerospace, hydraulics, medical equipment, electronics, and precision engineering. Its compact design allows efficient cutting in tight spaces, small bores, and thin-walled parts without part deformation or chatter.

This tool is compatible with Swiss-type CNC lathes, sliding head machines, and high-speed turning centers, delivering consistent groove width, accurate depth, and smooth surface finish in both small-batch and high-volume production. It is commonly used as part of tiny turning tools for CNC lathe, micro-grooving tools, and precision profiling systems.

The solid carbide construction ensures high rigidity and wear resistance, reducing tool changes and improving machining productivity. This makes it a preferred choice for industrial cutting tools suppliers, CNC tool manufacturers, and precision turning workshops that demand reliable and high-accuracy grooving solutions.

Reviews

There are no reviews yet.