THR QM 1.6*0.35*D4

Original price was: ₹6,252.00.₹2,938.00Current price is: ₹2,938.00.

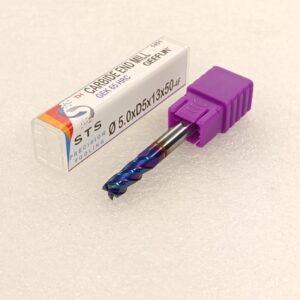

THR QM 1.6×0.35×D4 micro thread mill is a solid carbide CNC threading tool for M1.6 fine-pitch threads. Designed for stainless steel, aluminium, brass, and hardened materials, it delivers smooth thread finish, accurate pitch, and long tool life. The D4 shank provides strong rigidity for high-speed CNC machining. Ideal for electronics, medical devices, aerospace parts, and precision micro-threading applications.

5 in stock

We Ship All Over India

- Secure Payment Mode: Bank Transfer Only

- Returns & Refunds Available Within 7 Days

Description

THR QM 1.6×0.35×D4 micro thread milling cutter is a high-precision solid carbide thread mill designed for producing M1.6 × 0.35 internal threads in modern CNC machining operations. This precision thread mill is engineered for micro-threading, fine pitch tapping replacement, and high-accuracy thread profiling in small and delicate components where conventional taps cannot work reliably.

Manufactured from ultra-fine grain solid carbide and coated for wear resistance, this micro thread milling tool offers excellent edge stability, heat resistance, and long tool life when machining stainless steel, alloy steel, aluminium, brass, titanium, hardened steel, and engineering plastics. The optimized cutting geometry ensures smooth chip evacuation, reduced cutting forces, and vibration-free threading, even in blind holes or thin-walled parts.

The 1.6 mm thread diameter and 0.35 mm pitch make this tool ideal for electronics components, medical devices, watch parts, aerospace micro parts, hydraulic fittings, and precision mechanical assemblies. The D4 shank provides strong rigidity and secure clamping in CNC collets, allowing stable cutting at high spindle speeds without run-out.

Unlike conventional taps, the THR QM micro thread mill allows one tool to cut both right-hand and left-hand threads, adjust thread size through CNC programming, and produce perfect thread profiles with smooth surface finish. It also eliminates the risk of tool breakage inside the hole, making it safer and more economical for high-value components.

This tool is compatible with CNC machining centers, VMCs, high-speed milling machines, and Swiss-type machines, providing consistent thread quality, accurate pitch, and repeatable results in both small batch and mass production.

The THR QM 1.6×0.35×D4 is widely used by CNC cutting tools manufacturers, industrial cutting tools suppliers, and precision machining workshops that demand high-accuracy micro threading, low scrap rate, and long tool life.

Reviews

There are no reviews yet.