THR NPT 1/2×14 10.8xD12x75

Original price was: ₹18,122.00.₹9,967.00Current price is: ₹9,967.00.

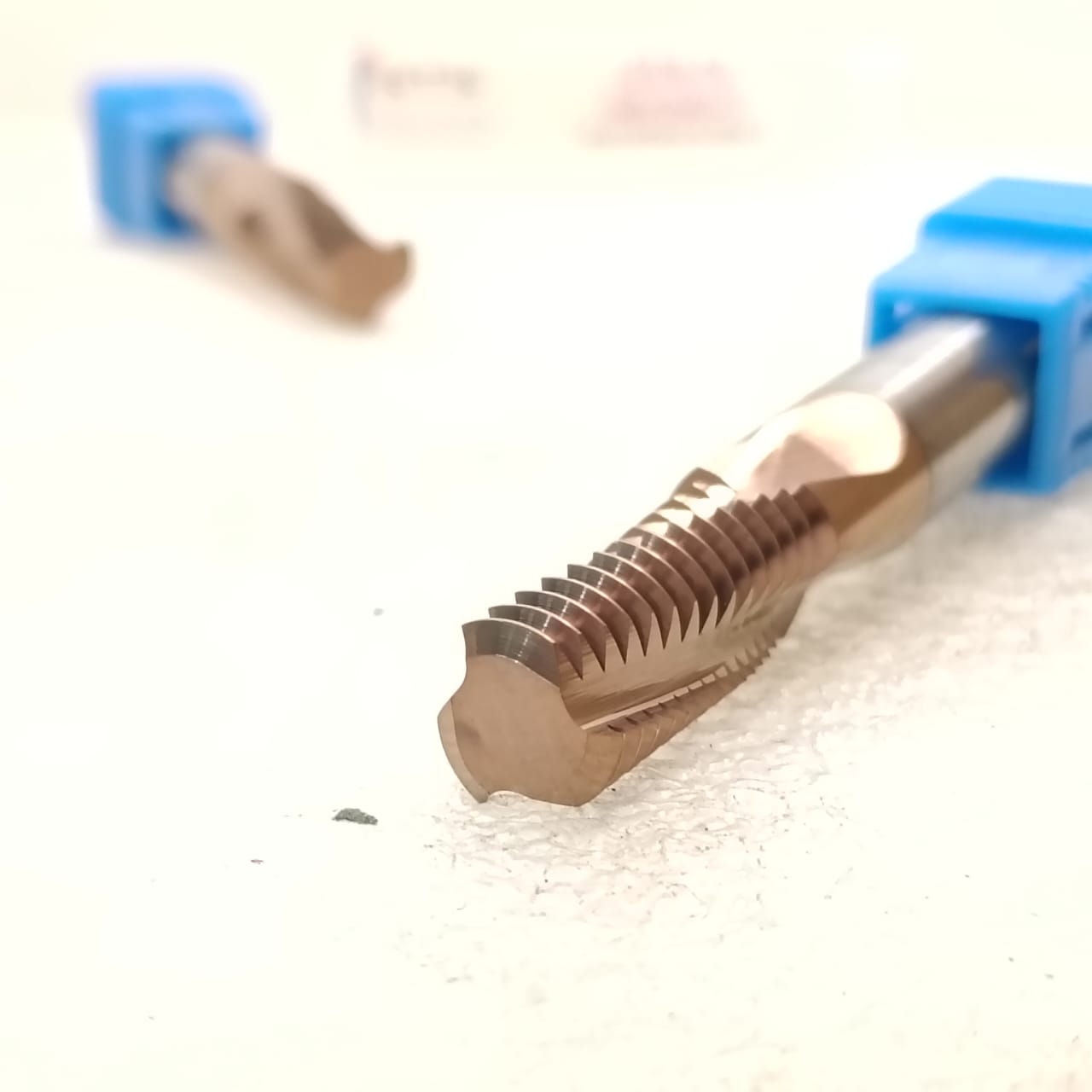

THR NPT 1/2×14 10.8xD12x75 is a high-performance solid carbide thread mill designed for precision CNC machining of NPT (National Pipe Taper) internal threads widely used in hydraulic systems, pneumatic fittings, mould cooling circuits, and industrial fluid connections. This tool is engineered to cut accurate 1/2-14 NPT threads with correct taper angle, clean profile, and smooth sealing surfaces in materials such as stainless steel, P20 steel, D2 tool steel, alloy steel, and hardened engineering metals.

Manufactured from premium micro-grain carbide rod, this CNC threading cutter delivers excellent wear resistance, thermal stability, and cutting edge strength, allowing stable and reliable operation in high-speed CNC machining centers. Compared to traditional tapping, thread milling offers better chip control, higher dimensional accuracy, and reduced risk of tool breakage, especially when machining tough or hardened materials. This makes it ideal for die & mould machining, aerospace components, automotive parts, and precision mechanical assemblies.

With a 10.8 mm cutting diameter, D12 shank, and 75 mm overall length, this tool provides the rigidity and reach required for deep and accurate NPT internal threading. The strong shank ensures low run-out, excellent concentricity, and smooth thread finish, resulting in leak-proof, perfectly formed pipe threads that meet industrial sealing requirements.

This thread mill is commonly searched as NPT thread mill, carbide thread milling cutter, CNC pipe thread tool, solid carbide threading tool, precision carbide tools India, and CNC cutting tools manufacturers, making it highly visible to buyers seeking industrial cutting tools suppliers and CNC tools supplier in India.

The THR NPT 1/2×14 10.8xD12x75 is widely used in hydraulic manifolds, pneumatic blocks, mould inserts, valve bodies, and fluid connectors, where precise thread geometry and reliable sealing are critical. Its ability to maintain consistent pitch and accurate taper makes it an essential tool for high-precision CNC machining environments.

Out of stock

We Ship All Over India

- Secure Payment Mode: Bank Transfer Only

- Returns & Refunds Available Within 7 Days

Description

THR NPT 1/2×14 10.8xD12x75 is a high-performance solid carbide thread mill designed for precision CNC machining of NPT (National Pipe Taper) internal threads widely used in hydraulic systems, pneumatic fittings, mould cooling circuits, and industrial fluid connections. This tool is engineered to cut accurate 1/2-14 NPT threads with correct taper angle, clean profile, and smooth sealing surfaces in materials such as stainless steel, P20 steel, D2 tool steel, alloy steel, and hardened engineering metals.

Manufactured from premium micro-grain carbide rod, this CNC threading cutter delivers excellent wear resistance, thermal stability, and cutting edge strength, allowing stable and reliable operation in high-speed CNC machining centers. Compared to traditional tapping, thread milling offers better chip control, higher dimensional accuracy, and reduced risk of tool breakage, especially when machining tough or hardened materials. This makes it ideal for die & mould machining, aerospace components, automotive parts, and precision mechanical assemblies.

With a 10.8 mm cutting diameter, D12 shank, and 75 mm overall length, this tool provides the rigidity and reach required for deep and accurate NPT internal threading. The strong shank ensures low run-out, excellent concentricity, and smooth thread finish, resulting in leak-proof, perfectly formed pipe threads that meet industrial sealing requirements.

This thread mill is commonly searched as NPT thread mill, carbide thread milling cutter, CNC pipe thread tool, solid carbide threading tool, precision carbide tools India, and CNC cutting tools manufacturers, making it highly visible to buyers seeking industrial cutting tools suppliers and CNC tools supplier in India.

The THR NPT 1/2×14 10.8xD12x75 is widely used in hydraulic manifolds, pneumatic blocks, mould inserts, valve bodies, and fluid connectors, where precise thread geometry and reliable sealing are critical. Its ability to maintain consistent pitch and accurate taper makes it an essential tool for high-precision CNC machining environments.

Reviews

There are no reviews yet.