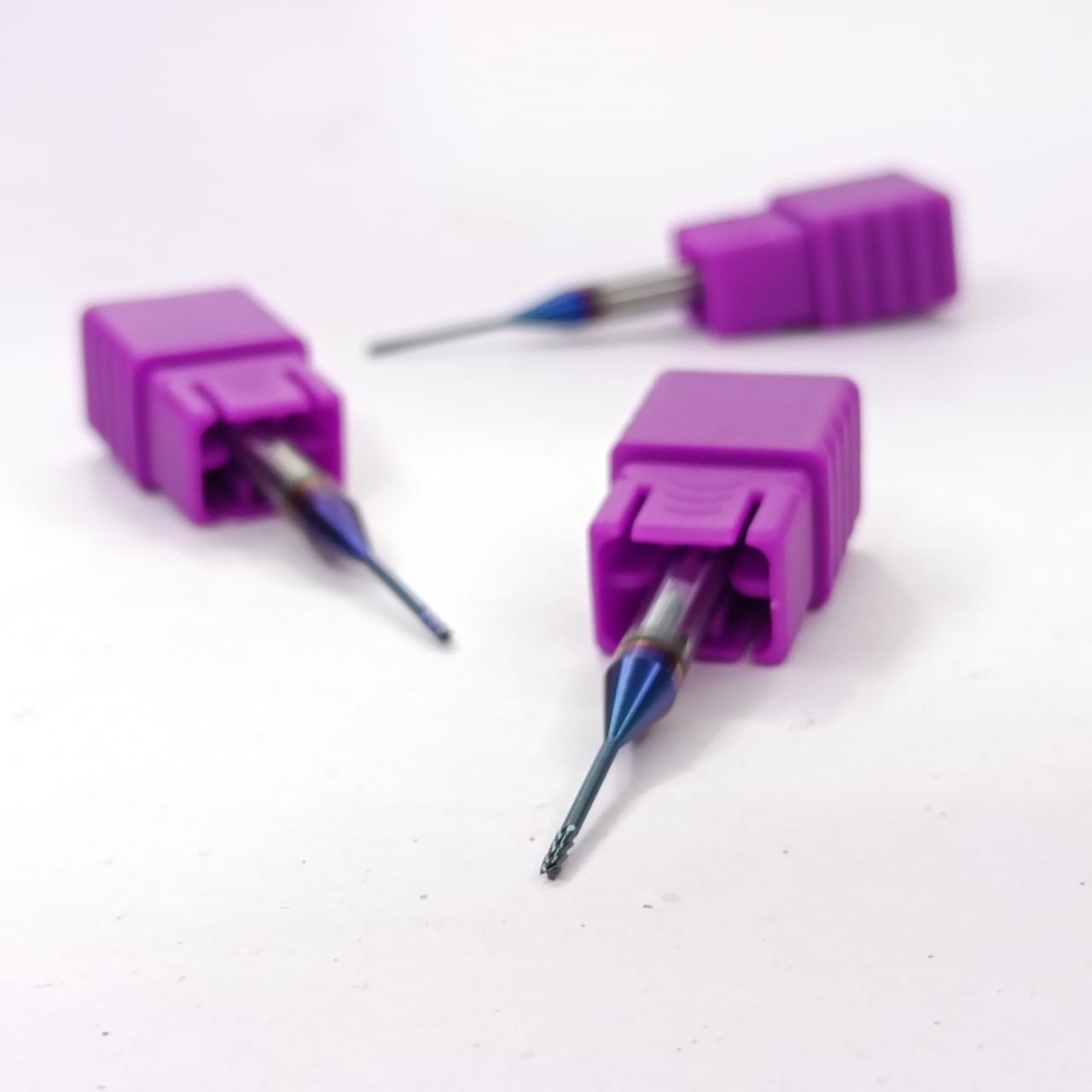

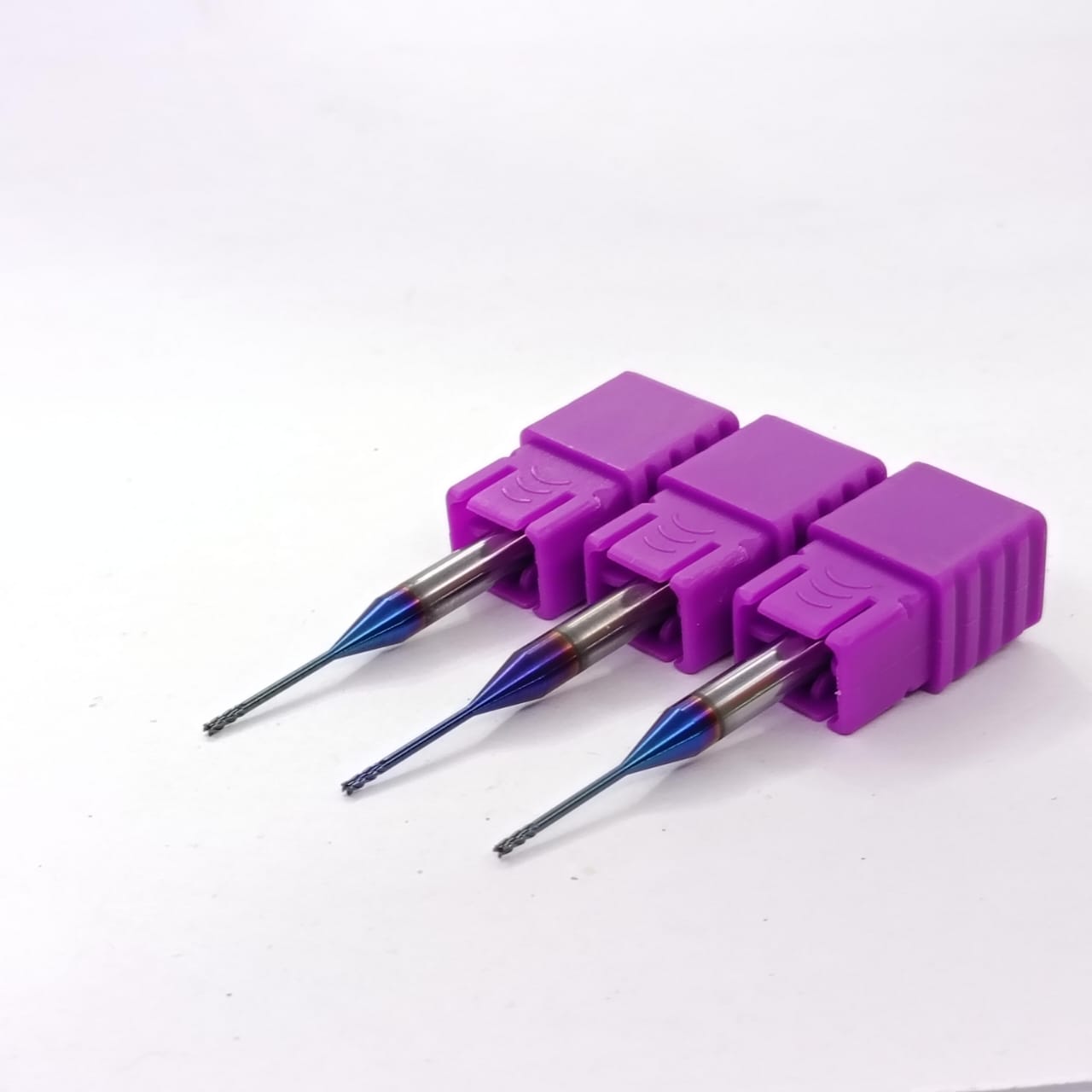

4HRE 65 1.0xD4x10x50-long neck end mill

Original price was: ₹2,462.00.₹985.00Current price is: ₹985.00.

4HRE 65 1.0xD4x10x50-long neck end mills for deep cavity and hard steel machining. Durable, precise, and ideal for tool & die industry.

16 in stock

We Ship All Over India

- Secure Payment Mode: Bank Transfer Only

- Returns & Refunds Available Within 7 Days

Description

4HRE 65 1.0xD4x10x50-long neck end mill is high-performance cutting tools specifically designed for machining ultra-hard materials, such as hardened steels up to 48-55 HRC (Rockwell Hardness C). These tools are made from premium-grade carbide, offering excellent wear resistance, high heat tolerance, and long tool life even under demanding conditions.

Key Features:

• High Hardness Capability: Engineered to cut materials up to 48-55 HRC, such as hardened tool steels, die steels, and other tough alloys.

• Long Neck Design: The extended neck allows for deep cavity milling, high-precision contouring, and improved accessibility in complex mold and die applications.

• Micro-Grain Carbide: Constructed from ultra-fine carbide particles to enhance strength and edge retention.

• Advanced Coatings: Often coated with high-performance layers such as BLUE NANO to improve heat resistance and reduce friction.

• Tight Tolerances: Manufactured with extremely tight tolerances for precision machining in industries like aerospace, medical, and mold & die making.

Applications:

• High-speed and high-precision machining of hardened steels

• Mold and die making with deep cavities or narrow slots

• Engraving, fine contouring, and finishing in high-hardness alloys

Benefits:

• Reduces tool change frequency due to extended life

• Provides excellent surface finishes and dimensional accuracy

• Minimizes vibration and tool deflection, even at long reach

Reviews

There are no reviews yet.